|

|

|

|

|

OPTIMORE Battery Condition Tester and Regeneration System

|

|

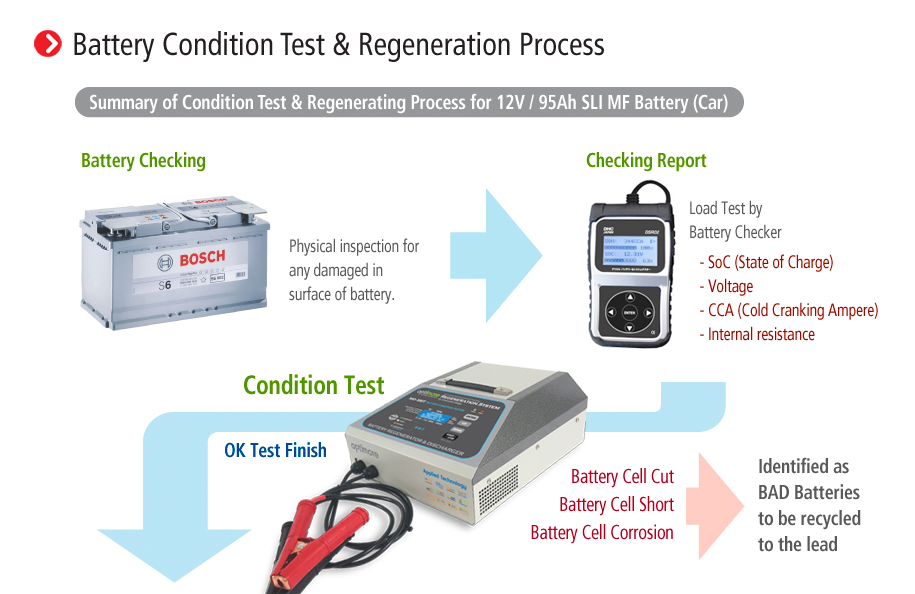

Battery condition tester whether to be regenerated or wasted. (For Used 12V Lead-acid Batteries)

|

| |

|

-> It takes 1~10 minutes for 12V battery condition test by MD-300T

|

|

-> Good or Bad batteries will be tested & identified by MD-300T.

|

|

|

|

|

All used 12V batteries - it is hard to identify that any cell was inferior among 6 cells (12V) prior to regeneration or charge process. Products of other competitors cannot identify short of electrodes and damaged cells before actual restoration procedure takes place.

So, we developed a new battery condition Tester (MD-300T ; 12V, up to 300Ah). It enables detection of short of electrodes and damaged cells within 1~10 minutes to identify. Such unique function cannot be found from any other existing products in the market and we are the first to put into commercial use.

|

|

|

|

Without MD-300T, nobody knows until finishing a regeneration process whether the battery was already damaged or not.

So, you will waste much time, labor cost and electricity uselessly. If you have OPTIMORE MD-300T, you can test all used 12V battery conditions prior to any process whether the battery condition is good to be regenerated or bad to be wasted.

- This is the only way to save time, labor cost, electricity cost and so on.

|

|

|

|

|

Why MD-300T will be the necessary equipment?

|

|

1. To test Used Batteries - There is no any digital tester or machine in the market to check used 12V battery condition whether to be regenerated or not. MD-300T will be the exclusive tester.

|

|

2. To save a lot of time and cost - A large majority of scrap or long time unused batteries should be tested, otherwise, much time & labor costs will be uselessly wasted. MD-300T will be a necessary equipment for all 12V battery users and sellers.

|

|

3. To avoid any lower performance - If any 2V cell is inferior (cell damage - Disposal state of Corrosion, Short of plates and Cell-Cut, impurity or lack of electrolyte(MF & RLA), Fall of active materials and etc.), a whole 12V battery should be discarded. So, all batteries should be tested and identified by MD-300T prior to any process.

|

|

4. To make the best charging performance - If a battery is doing any regeneration or charge process with having any damaged cell, the battery will be insufficiently charged or regenerated due to the lower damaged cell. So, all batteries should be tested and checked by MD-300T prior to any process.

|

|

5. To make the highest performance of all simultaneous regenerations - When any process with multiple batteries, if any one lower cell (2V) is mixed with other good batteries (e.g. 12V x 4~8 batteries simultaneously), the whole performance is restricted and lowered by one bad battery. So, all batteries should be tested and picked out all bad batteries by MD-300T prior to any process.

|

|

6. Simple and fast Identification - All Cell-cut and Cell-shorted batteries will be identified by MD-300T within 1 minute each.

|

|

7. High-Tech Identification technology algorithm - Cell-corrosion batteries (tested by less than 30% capacity) will be identified by MD-300T within 10 minute each.

|

|

|

|

|

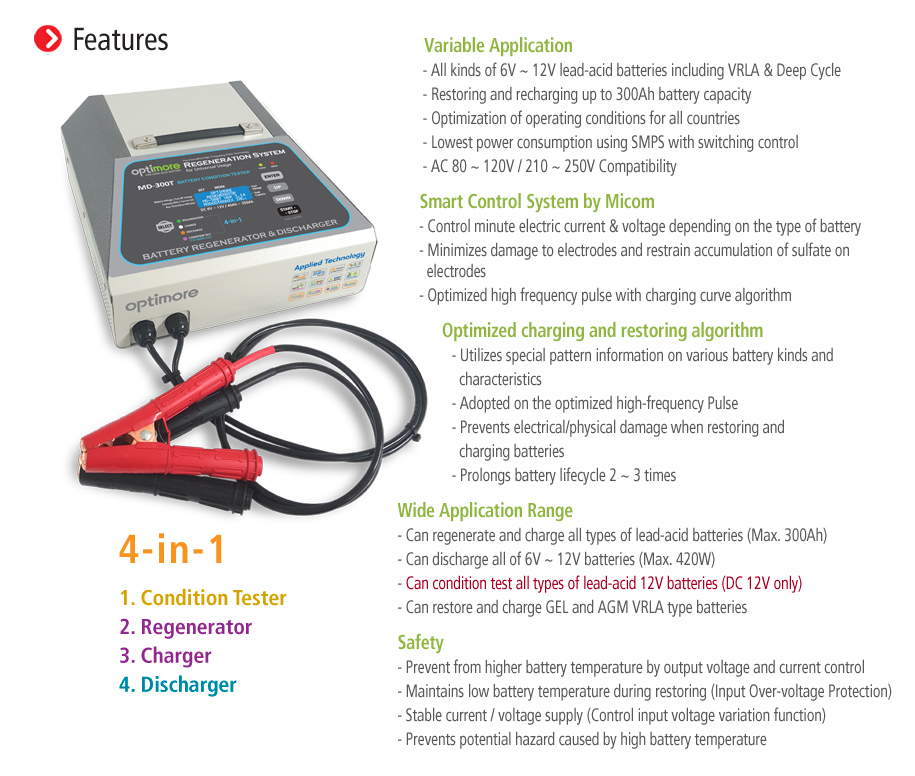

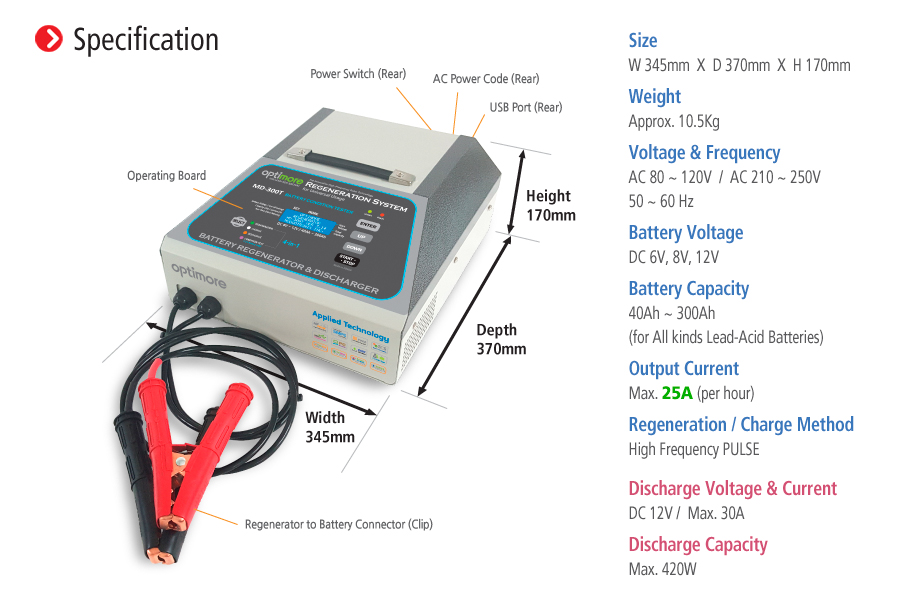

* MD-300T Battery Condition Tester & Regeneration System (4-in-1 multiple functions)

|

|

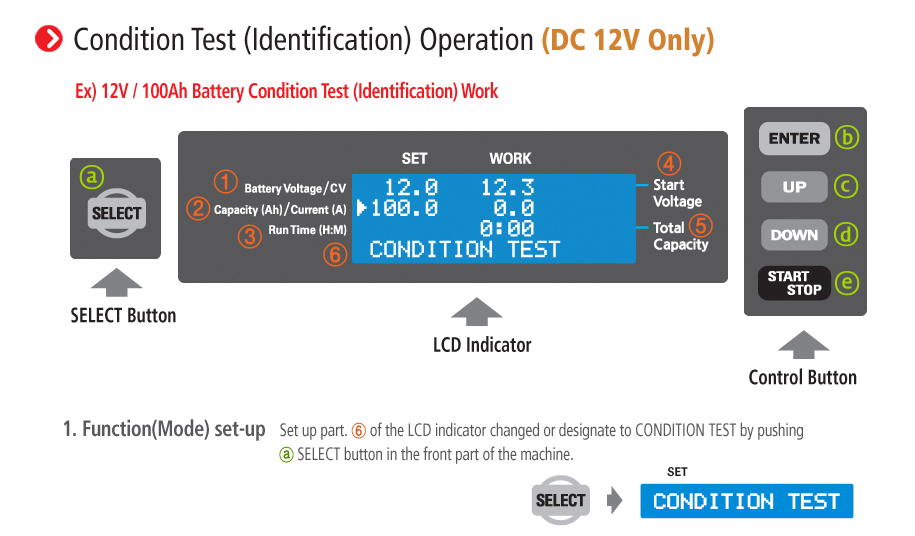

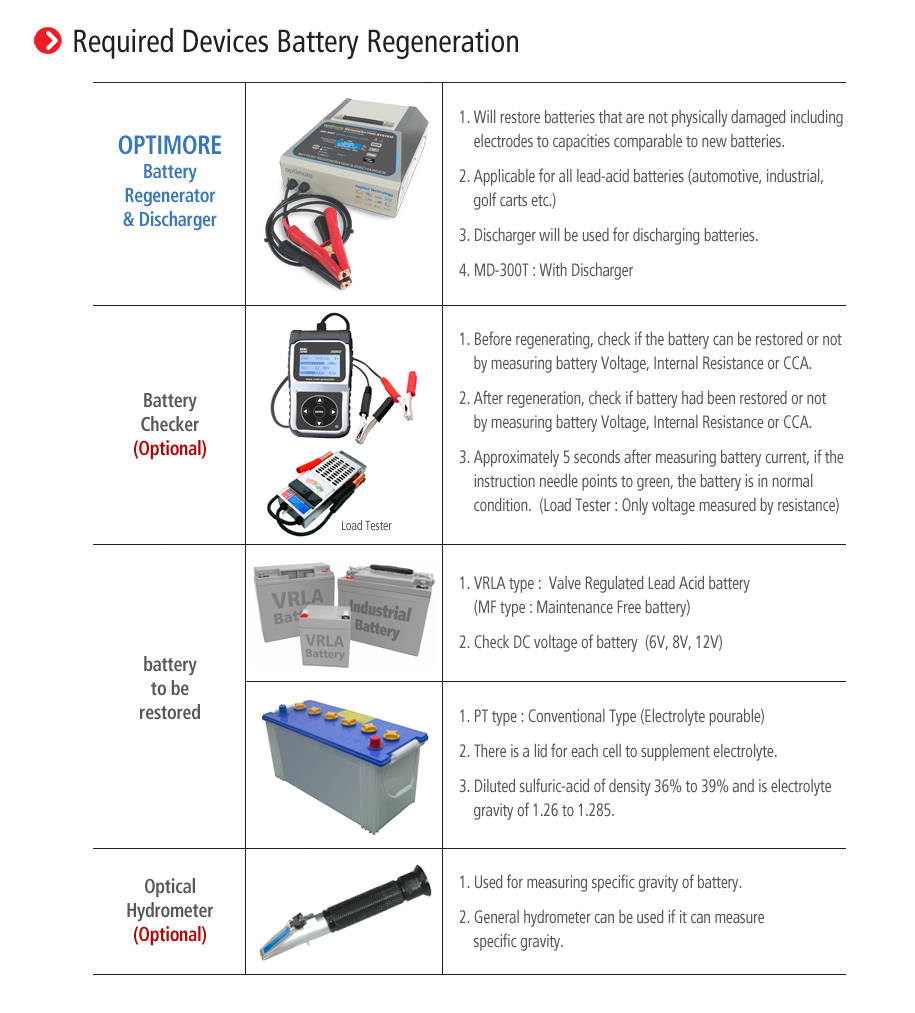

It is a very special all-in-one Battery Condition Tester for 6V~12V lead-acid batteries. It supports multi-functions of digital Regenerator + Charger + Discharger + Battery Condition Tester up to 300Ah at 12V batteries. For 12V battery, it is composed of 2 volts x 6 cells. It is hard to know about shorted circuit /cell cut/cell corrosion state and any damaged cells prior to a restoration process. In this reason, the other competitors must check on these damaged cases after finishing a process only. So, we have developed on 'MD-300T'. It can find the short of electrodes and damaged cells within few minutes before restoration procedure. Auto battery condition test function (whether to be restored or not - by 'CONDITION TEST' mode). By using it, most batteries will be assorted for targeting ones to be regenerated with our new MD-300T if they do not have any cell cut or short and internal cell's damage (corrosion). MD-300T has a full automated function to regenerate by setting of Voltage and Total capacity.

|

|

You can resell MD-300T to Battery wholesale, retail shops and Car repair shops as a battery physician. This item will be very good for battery sellers due to the superior restoration effectiveness for feeble new batteries which lost chemical activation and over-discharged - Dormant batteries.

|

|

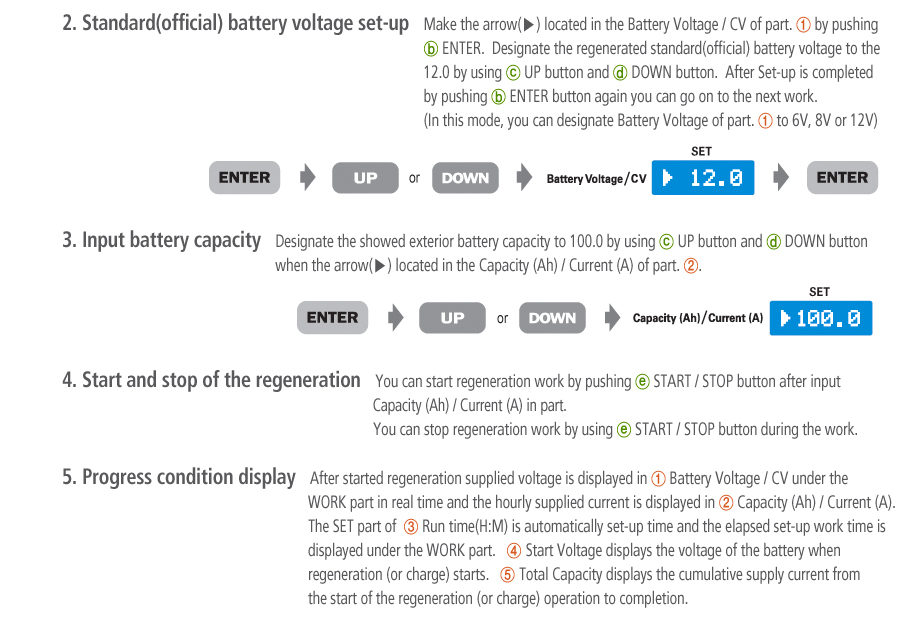

1. Battery Regenerator at 'REGENERATION' mode

2. Battery Charger at 'CHARGE' mode

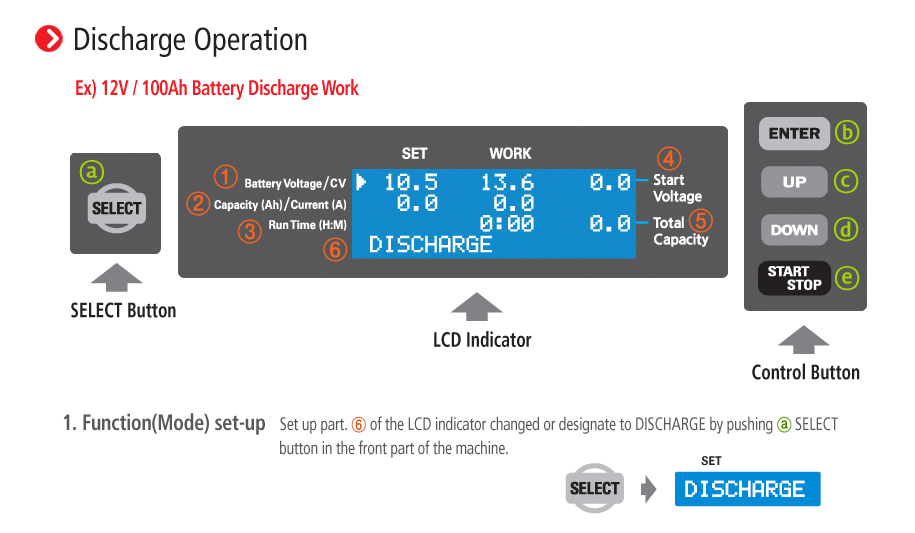

3. Battery Discharger (420 Watts) at 'DISCHARGE' mode

4. Battery Condition Tester at 'CONDITION TEST' mode (For 12V Battery)

|

|

Many used batteries have not good conditions, therefore, most used batteries should be tested on the inside cell conditions (2V x 6 cells = one 12V battery). With any battery tester, it is impossible to check that any 2V cell was already damaged among 6 cells (12V). If any 2V cell was already damaged among 6 cells, the whole 12V battery should be discarded.

|

|

MD-300T is not an analyzer, but a battery condition tester with Regenerator & Charger & Discharger - 4 modes functions combined for 6V~12V batteries. At 'CONDITION TEST' mode, it can test the battery conditions (12V, up to 300Ah) within a few minute. You can see it as 'CELL CUT', 'CELL SHORT' or 'CELL CORROSION' on the screen with a beep sound. If the battery is tested as a good battery to be regenerated, then you can see "OK TEST FINISH" on the screen with a beep sound as well. With MD-300T, you can regenerate all kinds of lead-acid batteries including 6V~12V VRLA AGM & GEL, Car, Deep Cycle, Solar and so on. The discharger supports up to 420 watts.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|